Injection MOLDING

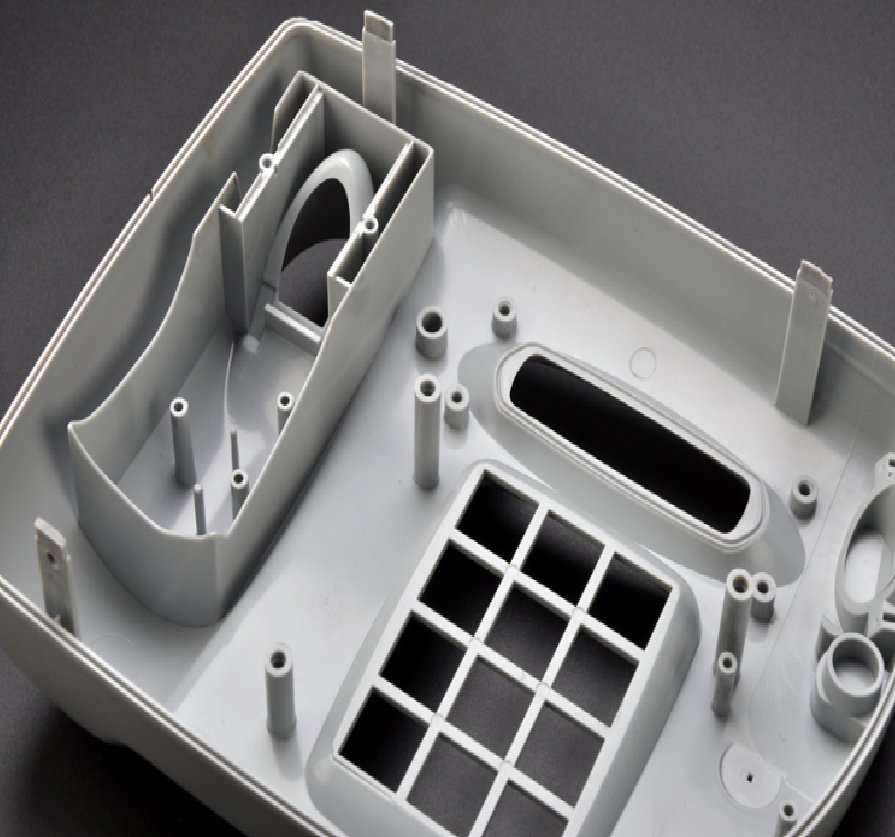

We manufacture our own molds in-house, and run our own injection molding lines in-house.

We can also assist you in design for manufacturability of your molding projects.

Your

Connection

We manufacture our own molds, and run our own injection molding facility. Our range of molds include low volume prototype single cavity molds, all the way through high volume multi-cavity molds. No mold is too simple or complex for us to help you develop. We employ parting-line gated molds, or sub-gated hot runner molds to best meet the design requirements of your part. We can offer design support to transfer your concept to production, and we will offer the most appropriate manufacturing method based on your needs.

Injection mold manufacturers will frequently tell customers that manufacturing a costly mold is the only way to see what the final product will look like. Since we specialize in model manufacturing (through machining) we will always offer customers the option of machining prototypes of their part that matches the geometry and appearance of the final injection molded product. This approach offers customers the security of "seeing" their final product before the costly capital expense of the production mold tool is incurred.

Manufacturing

Vacuum CASTING

Your molding volumes may start out small before growing to high volumes. This is where vacuum casting may offer you a molded product at low quantities before you're ready to commit to injection mold tooling for high volume production.

and Production

Rapid PROTOTYPING

- MACHINED PLASTICS

- 3D PRINTING (FDM & POLYJET)

- VACUUM CASTING

SURFACE FINISH:

Complete moldtec texture finishes are available and Pantone Matching System (PMS) colors available.